Composite Manhole Covers

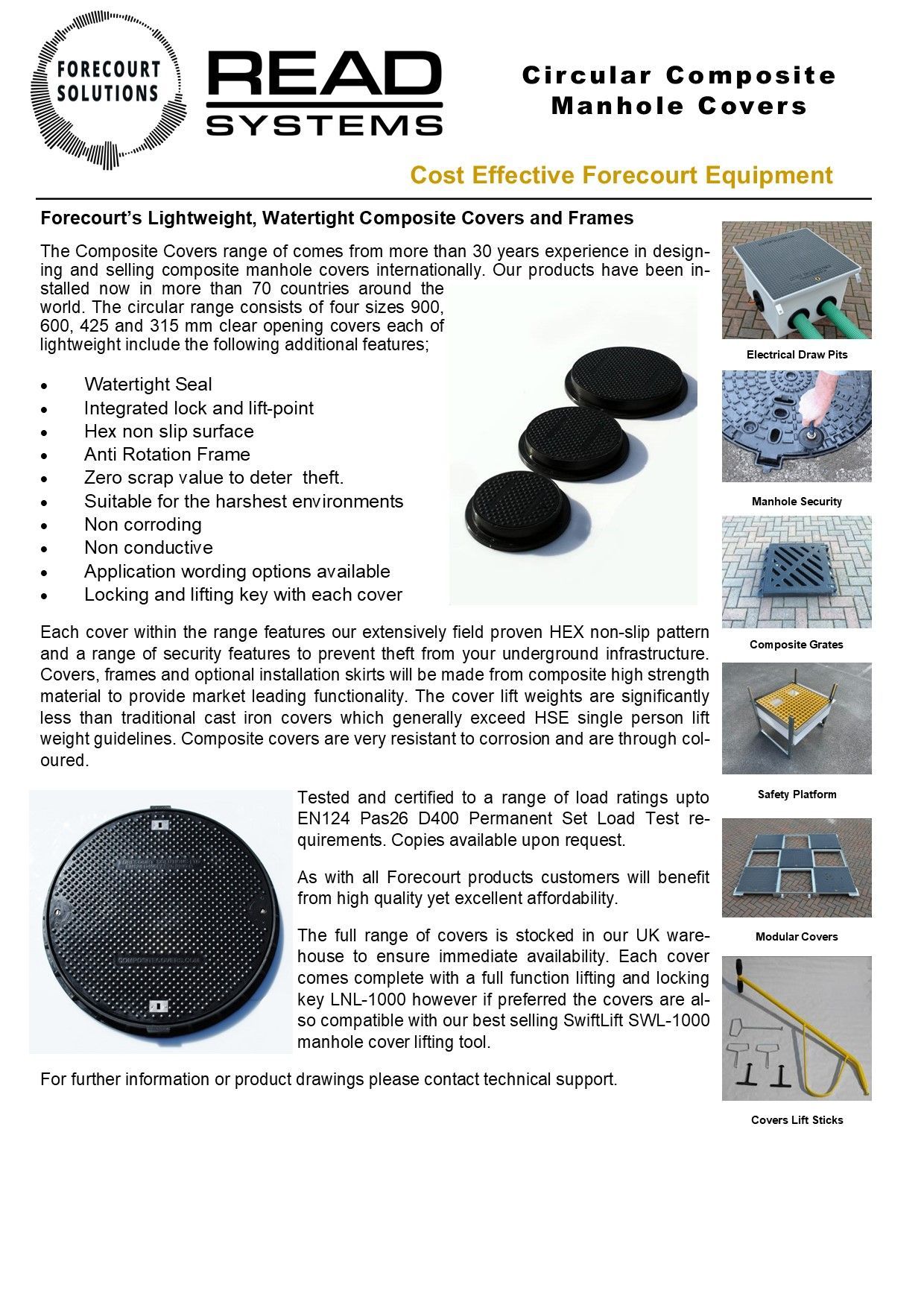

Manufactured from a resin and glass fibre mixture similar to fibreglass an environmentally friendly alternative to traditional iron covers. Composites also offer many other advantages over traditional cast or ductile iron covers such as lightweight, reduced risk of theft, non-conductive, rust-free and non-slip. Using up to 50% less energy in their production compared to cast and steel covers and they are full recyclable.

Such covers can be used in numerous applications some of the most common presently are;

Fuel Stations

The original market for which composite covers were developed because of the need for large watertight covers that were easily removable by station staff without the need for special lifting equipment.

Construction & Utility

Increasingly composites are finding their way into general construction for traffic signals, electricity, water and gas distribution, security sensitive applications, watertight applications and telemetry equipment applications. Or simply large covers which need to be removed on a regular basis and where weight of traditional cast iron covers would be problematic.

Modular Covers (large Span)

Modular covers solve the challenge of how to cover a hole or chamber where a single cover would require lifting equipment to assist in its removal. By making the overall cover into a number of smaller units suspended upon a structural frame manual removal for day to day access and inspection maybe achieved without the need for lifting equipment.